Pedals

IC & EV Pedal Boxes (2020-2021)

The main issue in this generation of pedal boxes was pedal slop. To solve this issue:

- Pedal lever & rod welded together as a singular component

- Self lubricating bushings added to ease rotation

- Torsion Spring added to counter torque from clutch cable

Before: After:

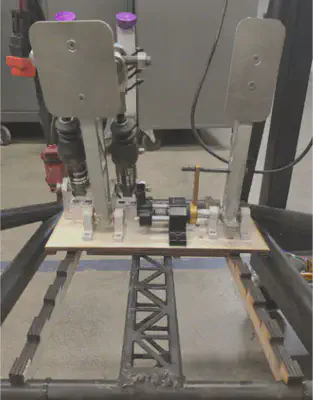

EV Pedal Box (2022)

As we were starting to transition to a purely electrical vehicle, we were able to construct the pre-Covid design for the EV pedal box. Once this was made there were many issues that arose:

- Discrepencies between some CAD and IRL components led to significant interference

- There was no real solution for attaching the springs meant to bring back the throttle pedal or for attaching the Break Over Travel Switch (BOTS)

- Adjustability of the entire pedal box system for different drivers, while designed for, was nearly impossible to actually implement

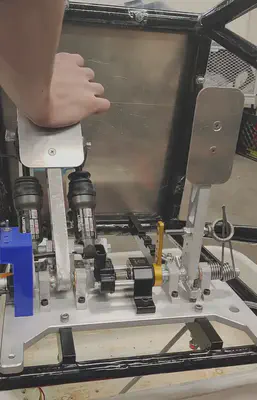

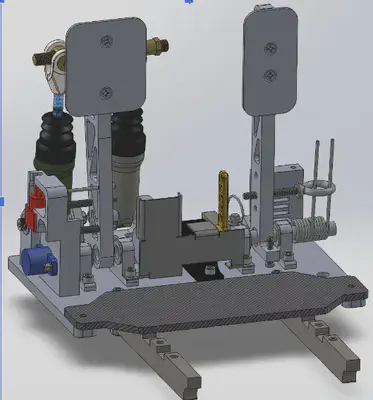

EV Pedal Box (2023)

Taking all the issues, we set out to make pedal box that was easily adjustable and had all the components properly encompassed in the baseplate.

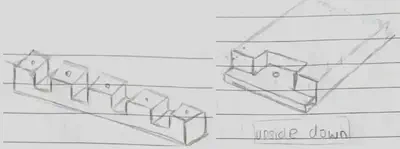

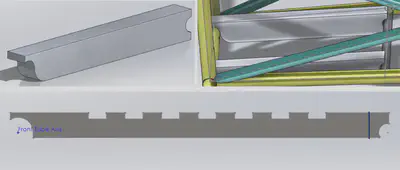

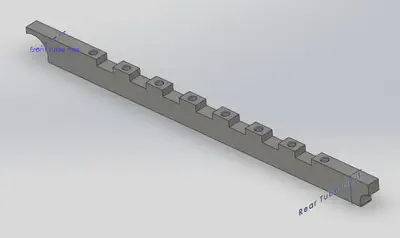

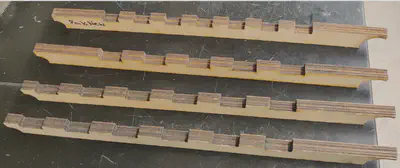

A complete redesign of the baseplate and chassis attachment mechanism was necessary. We went through several prototypes and iterations, eventually settling on a two rail system. The baseplate would slot into these two rails, and both would be milled to ensure proper sizing.

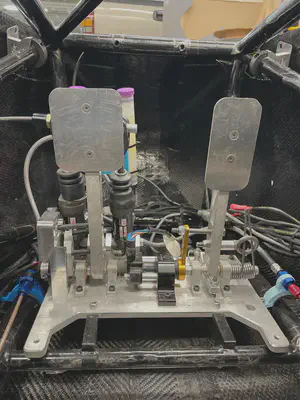

Once we were confident in our rail and baseplate design, we designed a proper BOTS holder and combined it with the Brake Sensor Encoder (BSE) mount. We then worked to properly attach the springs to provide enough force to bring the throttle pedal back. The final pedal box is below:

Manufacturing

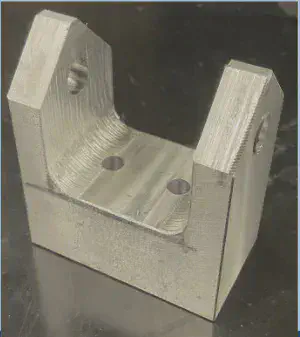

Milling the master cylinder clevises:

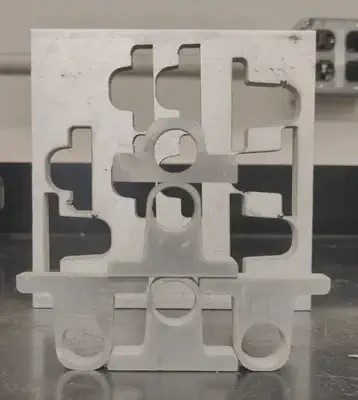

Waterjetting pedal levers and supports:

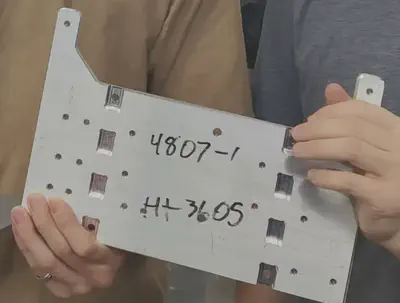

Waterjetting and Milling Baseplate:

Pedal Ratio Testing

To confirm that our understanding of the system was correct, we tried a few different orientations of the brake pedal and master cylinder system. For each orientation:

- The brake lines were connected to calipers, then brake pressure transducers (BPTs), then voltmeters for front and rear braking.

- 0.5-4.5 volts and 0-200 bar are linearly related, so by performing linear regression the relation is: Bar=Volts*50-25

What we found was that the smaller the angle between the master cylinders and brake pedal at their attachment point, the greater the force that is translated from the driver’s foot into braking. So, our near vertical master cylinder configuration would give us enough braking force.