Food Printing

This assignment focused on two main shapes: a twisted pyramid and a spirograph. Cream cheese was the main material used for the prints, with peanut butter being a secondary material.

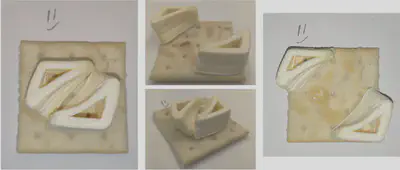

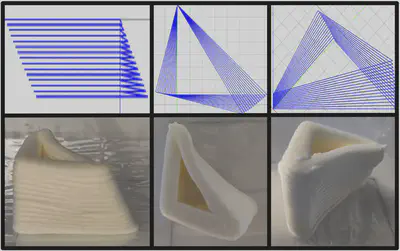

Twisted Pyramid

To generate this shape, I worked with the vertices of a triangle. I wanted a twisted pyramid shape that decreased in size as it increased in height, so the vertices had to rotate and get scaled down with each iteration. Once this was done, the new vertices get appended to a list in terms of GCode and the loop restarted. Once the entire structure is complete, a GCode file is compiled and can be run straight into the food 3D printer.

Factors that can be changed within the code:

- Side length of the triangle generated (size)

- Scaling factor per layer

- Number of layers

- Layer height

- Change in angle per layer

- Feedrate of the material

- Extrusion rate of the material

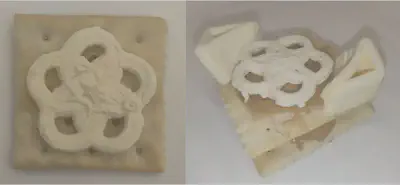

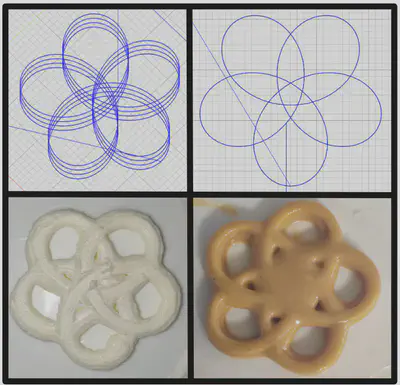

Spirograph

For this shape, I used the equations of an epicycloid to generate the curves of the spirograph. The equations give (x,y) coordinates that are appended as GCode. Changing the radii of each circle changes the shape of the spirograph (number of loops present).

Factors that can be changed within the code:

- Radius of the large circle

- Radius of the small circle

- Distance from the center of the small circle to the pen point

- Layer height

- Number of total lines drawn (layers)

- Feedrate of the material

- Extrusion rate of the material

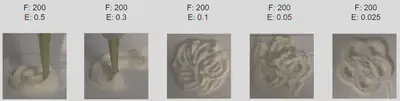

Printing Calibration Tests

3D printing with food is difficult because of the consistency of materials. Calibration is necessary to obtain the correct feedrate and extrusion such that the print actually comes out how you programmed it.

Final Plating